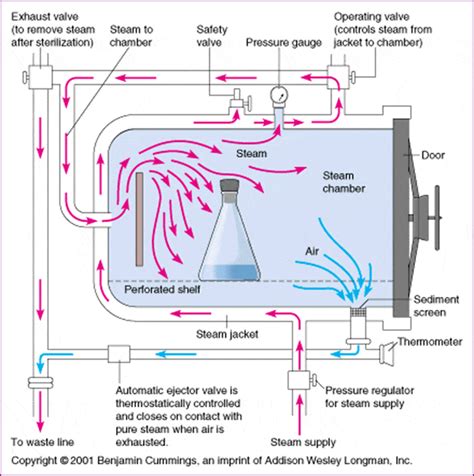

autoclave chemical stability|autoclave conditioning : ODM The basic principle of steam sterilization, as accomplished in an autoclave, is to expose each item to direct steam contact at the required temperature and pressure for the specified time. Thus, there are four parameters of steam sterilization: steam, pressure, . Parker Autoclave manifolds minimize space requirements and reduce the installation time necessary to plumb a pressure system. Transitions in system line sizes and tubing pressure can be accomplished through a specialty .

{plog:ftitle_list}

View and Download SciCan STATIM troubleshooting manual online. CASSETTE AUTOCLAVE. STATIM laboratory equipment pdf manual download.

The basic principle of steam sterilization, as accomplished in an autoclave, is to expose each item to direct steam contact at the required temperature and pressure for the specified time. Thus, there are four parameters of steam sterilization: steam, pressure, .

The treatment method to deactivate viable microorganisms from objects or products is termed sterilization. There are multiple forms of sterilization, each intended to be applied for a specific . Steam autoclaving and microwave method can be used as an alternative method to chemical sterilization as an effective method for disinfection of elastomeric impression materials. Background: Impression materials during impression procedure often get infected with various infectious diseases. Hence, disinfection of impression materials with various disinfectants is .

A similar effect has been previously reported: the chemical stability of the autoclave wall severely influences the corrosion of herein investigated samples [9]. This may be due to the samples (and autoclave wall) competing for attack of the mineralizer and depletion of the mineralizer by binding in soluble compounds and saturation of the .The results of these studies allow us to compare quantitatively the chemical stability versus water (corrosion rate from ~150 µm/day to less than 0.25 µm/day under 200–500 °C/15–80 bar PH2O) and to go further in comprehension of the aging mechanism of the membrane. . Autoclaves As summarized in Table 1, the four non-optic autoclaves .

The purpose of this study is to evaluate and compare the effect of autoclave and chemical sterilization on the dimensional accuracy and stability of two elastomeric impression materials.Methods: A total of 40 impressions were made with a special impression making device with 2 types of elastomeric impression materials polyvinyl siloxane and .Apart from the IL concentration and chemical structure, the buffer concentration and pH were evaluated in order to address their impact on the dsDNA stability. It is well-known that the pH influences the dsDNA stability and structural integrity (Lindahl and Nyberg, 1972; Cheng and Pettitt, 1992). In this work, the pH was controlled by the use . 2.1. The High Temperature and High Pressure Autoclaves. Table 1 lists the specific working conditions of autoclaves constituting the platform present in Laboratory of Dynamics, Interactions and Reactivity (LADIR). This autoclave platform was developed in direct relation with the study of a water steam electrolyser prototype allowing the low cost of hydrogen production .materials after chemical, autoclave, and microwave sterilization. In the present study, microwaving method showed highest dimensional changes followed by autoclave method and chemical sterilization (Tables 2 and 3). This could be because . stability of elastomeric impression materials disinfected

The present study showed that all the disinfection procedures produce minor dimensional changes of impression material. However, it was within American Dental Association specification. Hence, steam autoclaving and microwave method can be used as an alternative method to chemical sterilization as an .

The basic principle of steam sterilization, as accomplished in an autoclave, is to expose each item to direct steam contact at the required temperature and pressure for the specified time. Thus, there are four parameters of steam sterilization: steam, pressure, temperature, and time. . Typically, chemical indicators are affixed to the outside . Conclusion VSE exhibited excellent dimensional stability than PVS under both chemical immersion and microwave irradiation. . effect of autoclave and chemical sterilization on the dimensional . According to ANSI/AAMI ST79 Comprehensive guide to steam sterilization and sterility assurance in health care facilities, internal chemical indicators can be a Type 3, Type 4, Type 5, or Type 6.However, Types 5 and 6 are preferred for internal pack monitoring as they provide the user with more information on critical sterilization parameters. 1 The table below .

Superior chemical stability of UiO-66 metal-organic frameworks (MOFs) for selective dye adsorption. Author links open overlay panel Farhad Ahmadijokani a, . The mixture was heated at 120 °C in an autoclave and cooled to ambient temperature, which then centrifuged at 7000 rpm for 15 min to separate the nanoparticles. Subsequently, white .

Title: User Guide 23: Chemical Stability of Consumables Author: Jana Schmidt Subject: Consumables such as Eppendorf Tubes® and pipette tips have to withstand the different kinds of stress and strain encountered in everyday laboratory work, e.g. when centrifuging and autoclaving, and at the same time are exposed to chemical reactions. This in vitro study compared the effects of chemical disinfectants and UV irradiation on the dimensional stability of polyether impression material and found that disinfection with 1% sodium hypochlorite or UV rays for 20 min maintained dimensional stability in polyether impressions. . Chemical disinfection and autoclave sterilization had no . Bustos et al. reported an effective disinfection with minimal changes in dimensional stability and surface integrity when alginate and silicone impression materials were immersed in 0.5% NaOCl or 2% glutaraldehyde for 5 min rather than for 10 min. Ahila and Thulasingam reported insignificant dimensional changes of silicone impression materials . In summary, the influence of high temperature steam sterilization on the rubber stopper used in the medical industry is manifold. These effects not only depend on the physical and chemical conditions of sterilization, but are also closely related to the composition, chemical stability and frequency of use of rubber materials.

The impact of moist-heat sterilization (autoclaving) on the chemical stability of parenteral solutions was examined using two heat-labile products, clindamycin phosphate and succinylcholine chloride injections, as examples. A nonisothermal kinetic model was . Consequently, we have developed autoclaves equipped with a sapphire window, allowing in situ Raman study in the 25-620 °C temperature region under 1-50 bar of water vapor/gas pressure, both with and without the application of an electric field. . The results of these studies allow us to compare quantitatively the chemical stability versus . An autoclave is a vital tool in scientific and medical laboratories, essential for ensuring the sterility of equipment and materials. . Provides stability and support, ensuring the autoclave remains upright. Steam Generator/Electrical Heater (cont.) . autoclave tapes with heat-sensitive, chemical indicators are adhesive-backed paper tapes .

is graduated pipette more accurate than volumetric

A leak on the autoclave may let air in during those vacuum pulses. There may be air (or other “non-condensable gasses” like CO 2) in the steam . . • Expectations are excellent stability and uniformity of tempertature inside the chamber. 36 Standard . However, post-autoclave assessments at 1, 5, and 10 cycles demonstrated no statistically significant differences in tensile strength (p = 0.058) and hardness (p = 0.52) for PP/NR ratios of 100/0 . Thus, autoclave sterilization was considered as an effective alternative effective method for disinfecting silicone impression materials (Kotha et al., 2017). Kamble et al. also stated that steam autoclaving is effective and can be used as an alternative to chemical disinfection of elastomeric impression materials (Thota et al., 2014). They . The primary means of sterilizing compounded preparations are: terminal sterilization, which includes dry heat or autoclave, and filtration.” . FormulaPlus extended BUDs address the chemical stability of the formulation determined by a stability-indicating assay. A passing sterility test is required prior to considering applying for this .

Similarly, chemical disinfection and autoclave sterilization produced no statistically significant effect on the surface roughness and wettability of vinyle polysiloxane impression materials . Chemical disinfection alone is insufficient hence autoclave at high temperature is necessary to kill microbes and their spores. Microwave sterilization is used as an alternative approach, where electromagnetic energy from the microwave is considered to be alternative to the conventional method. 4 This study measures the dimensional changes of .The Impact of an Autoclave Cycle on the Chemical Stability of Parenteral Products Jagdish Parasrampuria , Luk C. Li , Alan Dudleston , Hao Zhang PDA Journal of Pharmaceutical Science and Technology Jul 1993, 47 (4) 177-179;

autoclave for sterilization

The basic principle of steam sterilization, as accomplished in an autoclave, is to expose each item to direct steam contact at the required temperature and pressure for the specified time. Thus, .

autoclave chemical stability|autoclave conditioning